Product Development

| Calculators | Wind Type | Fold | Color | Cuff |

| Material | Sequential Numbering | Packing Method | Shipping Method | Labeling Method |

Understanding the product you pack, shelf life requirements and the machine type you use will help us in recommending the best poly for your application. For example is your product dry or is it wet? Does is freeze? Does it have sharp edges? Do you pull a vacuum or nitrogen flush? What are the shelf life requirements? Is there an Oxygen transmission requirement, etc.? Finally have there been past issues or concerns with the packaging, such as tearing over the box corners, straight line tears, carbon or bad seals. This information will help us provide a solution to you that will give you the best poly you need and most importantly keep the cost down. Time and time again we see food manufactures using poly that is way over engineered for their application which increases your cost.

In addition to knowing what you pack we want to help you pack it. Your machine type, run speeds, and type of box and product will help us make a recommendation. You may want to consider the following: Seal type, flat bag or gusseted bag, material color, bag strength, OTR and shelf life, lot coding printed on each bag, Strength characteristics such as MD and TD, Wind direction, separated or perforated?

Want to see some examples of our products? Visit our YouTube channel.

Calculators

Calculators to determine how many rolls fit on a pallet

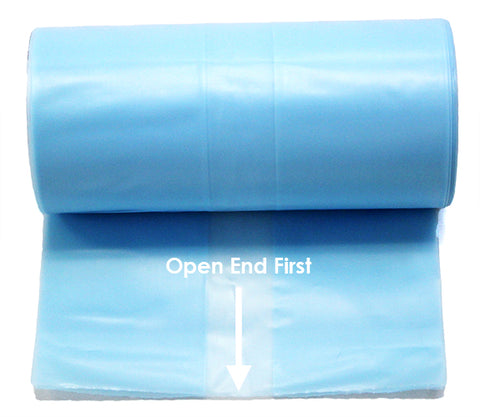

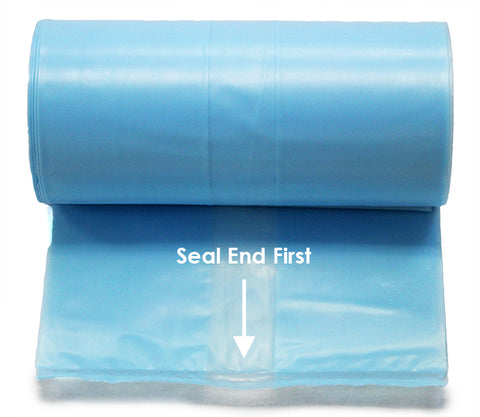

Wind Type

|

|

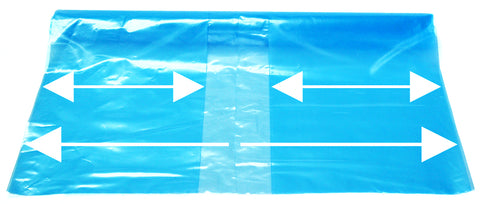

Fold

Gusseted Bag

|

|

|

Flat Bag

|

|

Center Fold Sheeting

|

J Fold Sheeting

|

|

C Fold Sheeting

|

|

M Fold Sheeting

|

|

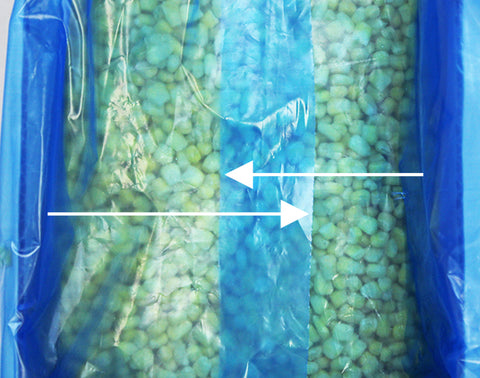

Color

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cuff

|

Cuff edges meet |

Cuff edges overlap a specified amount eg: 2" |

Cuff edges overlap to box edges |

Material

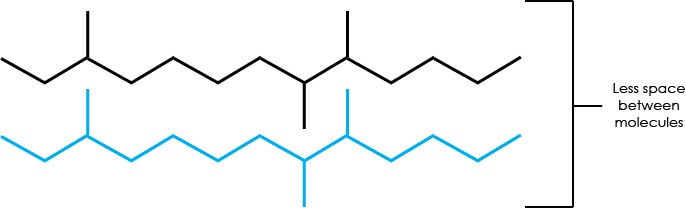

Low Density Polyethylene

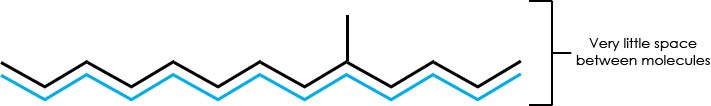

Excessive molecular branching leads to a less compact molecular structure and a low density.

Linear Low Density Polyethylene

Significant number of short branches. Because it has shorter and more branches its chains are able slide against each other upon elongation without becoming entangled like LPDE which has long branching chains that would get caught on each other. This gives LLDPE higher tensile strength and higher impact and puncture resistance than the LDPE.

High Density Polyethylene

Minimal branching of its polymer chains. Because it is denser it is more rigid and less permeable then the LDPE.

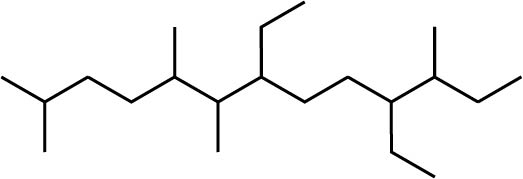

Metallocene, Octane, Hexine

The bonds between the chains are not very strong. However, because they are so long, there are more bonds holding it together than polyethylene with shorter chains. These long chains give UHMW high tensile strength. The longer chains serve to transfer load more effectively to the polymer backbone by strengthening intermolecular interactions. This causes the material to be very tough and gives it the highest impact strength of the polyethylenes.

Sequential Numbering

|

We can print: • Anywhere on the bag |

|

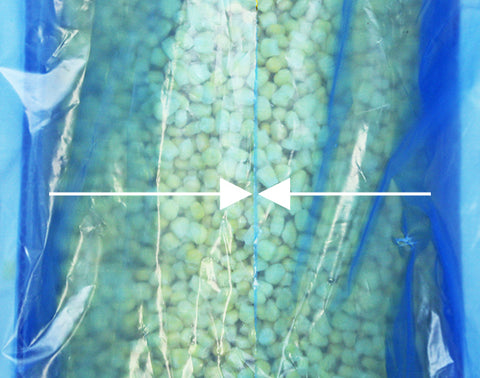

Packing Method

|

Roll |

|

Shipping Method

Step 1• Rolls are wrapped and stacked either vertically or horizontally on the pallet. |

|

Step 2• Box is closed. |

|

Step 3Pallets are stacked 2 high, unless otherwise specified. |

|

Step 4• Pallets are secured. |

|

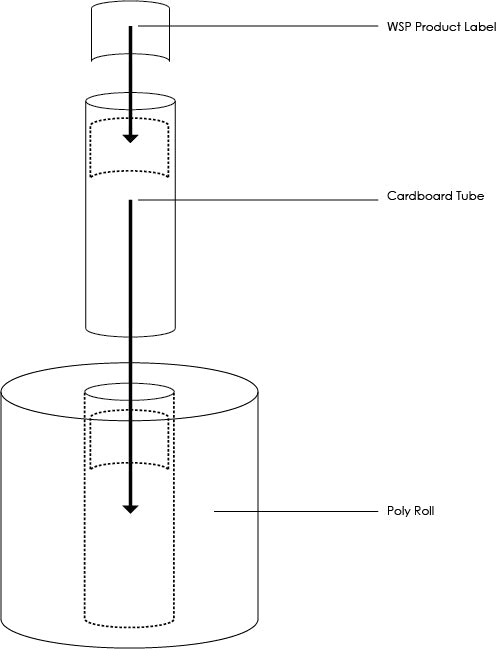

Labeling Method

Unless otherwise requested, our rolls are labeled as follows:

|

Box

Box