Capabilities

| Extrusion | Inventory Management | Traceability | Lab Testing |

What exactly can WSP do for your company?

Extrusion

Our expertise, quality systems, and our proprietary techniques and equipment are what allow us to manufacture your product to exacting standards. We can manufacture:

Our expertise, quality systems, and our proprietary techniques and equipment are what allow us to manufacture your product to exacting standards. We can manufacture:

• Film to 1/8th of an inch

• Gauges from 0.00045 to 0.011

• Sizes from 4 inches to 120 inches

• Any specific weight and size of tubing or bag roll

• A wide variety of blended, HDPE, and HMW materials.

Some examples of what we can produce are:

• Roll Stock or Stock in Cases

• Single-Wound Sheeting

• J Sheeting

• Center Fold Sheeting

• Plain, Lay Flat Tubing

• Gusseted Tubing

We can also produce different poly blends for a variety of different characteristics, such as:

• Anti Static

• Low Slip

• High Slip

• Non Skid

• EVA

• Tint/Opaque

• Custom Colors

Inventory Management

We offer a no cost inventory management program bases upon a Mid / Max agreement. We have ample space to facility your JIT program. We can offer local warehousing with a third party partner in various points around the country as determined by the needs of each facility.

Although we ask for 3 weeks of lead time to fulfill your orders, we are here for you and we know things happen that change your time tables. When you call us and ask this question: “When can you get me product?” our team will ask you, “When do you need it?” We believe it’s what you do for your customers in their time of need, not what you do when its business as usual.

Traceability

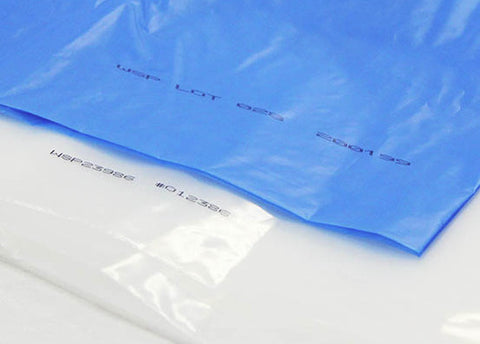

Our traceability program and SOP’s properly addresses everything from the raw materials we receive to the products we ship to you.Beyond that we offer our ability to print dates, serial numbers, company names, and just about anything you can think of onto your product. Then, we keep a sample of every run at our facility. If something happens, you need to recall a product, or you are noticing problems with a run, we are able to pull that sample for you.

Click here to see how we label our product.

Back to the TopLab Testing

We tell our customers we have been sniffing poly for over 30 years and we can tell you a thing or two about it just by touch. Above that we have built an in house lab for comparative testing. We can test Elmendorf tear, Tensile and dart impact in house. For tests such as Oxygen transmission, Spectrum Analysis and Opacity we work with a third party lab.

Why do we test film? For a few reasons: The first is we want to make sure the film we are going to make for your meets or exceeds the specifications of your current film if you are switching to us as your new film supplier. The second is to validate that on an ongoing basis your film is still meeting the specs we created for you based on your application. The third reason is used when you need a film designed around a new application or maybe you are trying new materials to take advantage of cost savings but want to know the properties you need are there.

Typical tests performed include:

Elmendorf Tear ASTM D1922

Scope: This test is used to compare the tearing resistance of two comparable plastic films or thin sheetings. This test method covers the determination of the average force to propagate tearing through a specified length of plastic film or nonrigid sheeting after the tear has been started, using an Elmendorf-type tearing tester. Two specimens are cited, a rectangular type, and one with a constant radius testing length. The latter shall be the preferred or referee specimen.

Drop Dart Impact Tester – ASTM D1709

These test methods cover the determination of the energy that causes plastic film to fail under specified conditions of impact of a free-falling dart. This energy is expressed in terms of the weight (mass) of the missile falling from a specified height which would result in 50 % failure of specimens tested.

Tensile Testing ASTM D638

This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed.

Oxygen Transmission Rate (OTR) ASTM D3985

This test method covers a procedure for determination of the steady-state rate of transmission of oxygen gas through plastics in the form of film, sheeting, laminates, coextrusions, or plastic-coated papers or fabrics. It provides for the determination of oxygen gas transmission rate (OTR), the permeance of the film to oxygen gas, and oxygen permeability coefficient in the case of homogeneous materials.